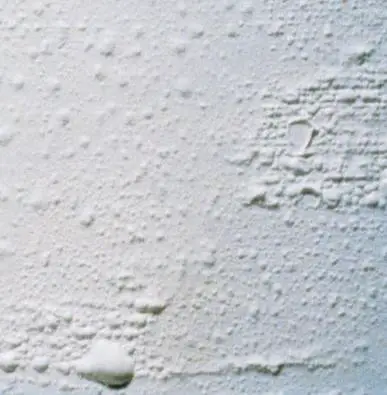

Defects in plaster

Plaster can be cracked or damaged due to the following causes:

- If the proportion of sand in plaster is excessive or low quality sand is used then the plaster can be cracked.

- If plaster is dried out because of improper curing then it can be cracked.

- Plaster should be placed properly with the background, otherwise it will get defected and fall apart slowly.

- After applying first layer it should be given the time to dry out before applying the second layer. Otherwise, hair crack may appear in the plaster later.

How to rectify defects of plaster

The defects of plaster can be rectified by following the below steps:

- Before plastering, water should be applied to the surface to make it wet so that the surface won’t suck water from the plaster.

- Don’t rub too much trying to make the surface smoother.

- Use good bricks in masonry works.

- Salt free water should be used in construction works.

- Efflorescence can be reduced by brushing and washing for couple of times. ZnSO4 and water mixture can reduce efflorescence drastically. You can also use H2SO4 with 5 multiple volume water mixture and wash the surface to reduce effloscence close to zero.

- When the surface is free from efflorescence then the paint should be applied.

- Moisture resisting layer should be provided adequately.