Stucco, which is a fine plaster that is used for coating wall surfaces or molding for architectural design purposes, has been around for centuries. There are regions where stucco is much desired and it has an appeal to it that people want within their homes. A new material has been created called Exterior Insulation and Finish System or EIFS. This is commonly referred to as synthetic stucco. It is made of lightweight polystyrene panels that are two inches thick and have an acrylic coating that does, in fact, mimic traditional stucco. How good is synthetic stucco? Let’s look at all the aspects of synthetic stucco including application, finishes, colors, problems, repairs and repair costs.

Synthetic Stucco Application

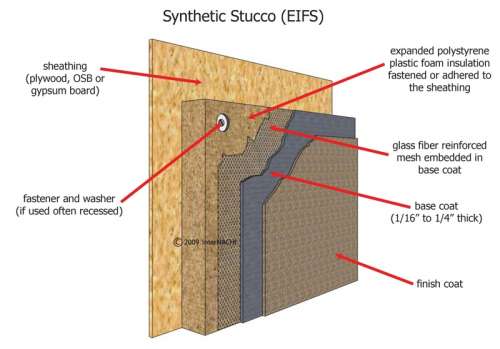

Synthetic stucco uses two layers: a base coat and a finish coat. It is installed over foam insulation. Use a base coat that is already mixed. This is more convenient than buying a base coat and then mixing it with sand and water. Install the insulation board or otherwise known as bead board insulation. It must be 1 inch thick. Secure the insulation board to the plywood wall or frame with ceramic coated screws and plastic washers.

After installing the insulation, it has to be backwrapped. This will protect the edges of the insulation from the elements. You will apply a base coat using a 6 inch spackle knife to the front, back and edge of the foam and then wrap it with plastic mesh. The mesh has to be worked into the base coat and then allowed to dry overnight.

Next, apply the base coat following the manufacturer’s directions. The base coat must be applied to the entire wall at a thickness of 3/8 to ½ inches thick. The base coat must dry for at least a day or longer. Apply the finish coat as a thin solid coat. Allow it to set up a bit and then use a trowel, keeping the trowel flat against the surface, be sure to make a pattern if you like. Allow the finish coat plenty of time to set up before making your pattern while doing the finish troweling.

Synthetic Stucco Finishes & Colors

- Zero VOCs, zero solvents – made without harmful solvents and cures without emitting and VOCs.

- Synthetic stucco is not brittle like genuine cement stucco. Formulated Solutions designed cementitious mortars and created a unique thin-setting cement finish that is very flexible and keeps the natural characteristics of traditional stucco.

- Breathability matters – moisture is the enemy. TESS Finish allows breathability and makes the synthetic stucco finishes last longer and hold up through the various elements.

- There are numerous colors and textures available for synthetic stucco that you cannot duplicate with traditional stucco. There is a style that is just right for any architectural design. Check with the manufacturer for color availability.

Synthetic Stucco Problems

Although synthetic stucco sounds like the ideal alternative to genuine stucco, it does not come without its problems. Once moisture becomes trapped in the wall cavity, it will stay there. This is a design flaw that provides no means for moisture to escape once it becomes trapped. The trapped moisture over time will eventually eat away the sheathing, the structural framing and even the interior finishes.

Another problem with synthetic stucco is mold which can build up within the moisture prone cavity wall. As air moves throughout the room and is constantly exchanges between wall cavities and indoor rooms, the mold can be carried into the living spaces.

The problem of trapped moisture initially was thought to be in moisture prone climates and attributable to improper application by the installer. Now, synthetic stucco is now causing problems in some dry, southwest climates.

Termites can also be a threat to a building that has synthetic stucco. Swarming termites can enter through any crack within a building and consume all wood products. Termites infested within synthetic stucco homes will cause more damage at a quicker pace.

Synthetic Stucco Repair

It is always important to take quick action to repair synthetic stucco as soon as the damage is found. Permanent repairs to synthetic stucco cannot be done, but temporary repairs can be made. There are several steps that you need to follow to ensure that the repair is done correctly.

1. Locate and Assess the Damage: First you have to find where the damage is and assess the severity of the damage. This will enable you to properly determine how the repair should be completed. The two most common damages to synthetic stucco are water damage and termites.

2. Determine the Appropriate Action: If termites are what have caused the damage, then an exterminator needs to be called to eliminate the termites. The exterminator will also assess other areas and determine the extent of the damage.

If water damage has occurred, then install flashing to the at-risk part of the roof. You should use valley flashing, rake flashing and diverter flashing should be used along the roof joints and then kick-out flashing where the roof meets the walls.

3. Caulking: The use of caulk in all the seams around the moldings of windows and doors plus the sill joints and window jambs will aid in keeping moisture from getting behind the synthetic stucco. Make sure that there is enough caulk being used that it begins to ooze out the edges, this ensures that it is sealing well.

4. Flashing Around the Windows: Make sure that window specific flashing has been installed around the sill of the windows as well as around any decks. There are several different types of specialized flashing that are made specifically for the different types of windows.

5. Flashing Around the Chimney: It is always best to install kick-out, cricket and cap flashing around the base of the chimney. This will help block out the water seepage where the chimney meets the roof.

6. Caulking Cracks: Be sure to apply caulk into any trouble spots or cracks that will need repairs but are not really large enough to require flashing. Many times termites can enter through unusual spots or cracks so use enough caulk so that some oozes out the edges and make a tight seal.

7. Flashing Any Trouble Spots: Flashing should always be installed where there are larger trouble spots that caulk alone cannot seal. There are numerous styles of flashing to choose from to go with the aesthetic look of the building.

8. Watch for More Damage: Be sure to stay vigilant about any areas that have been repaired. If you notice the repair is not holding or further damage is occurring, another fix will need to be done. If the damage is extensive, re-applying the stucco may be necessary.

Synthetic Stucco Repair Cost

Repair costs for synthetic stucco will vary depending on the severity of the damage. Most stucco repairs can be completed with standard tools and equipment for an average cost of $478. Repairing chipped stucco can range from $251 to $911. Cracked or stained stucco will typically cost the same as chipped stucco.