Concrete shrinks as it dries out. It is advisable to minimize such shrinkage by using concretes with the smallest possible amounts of water and cement compatible with other requirements, such as strength and workability, and by thorough moist-curing of sufficient duration. However, no matter what precautions are taken, a certain amount of shrinkage is usually unavoidable. If a slab of moderate dimensions rests freely on its supports, it can contract to accommodate the shortening of its length produced by shrinkage. Usually, however, slabs and other members are joined rigidly to other parts of the structure and cannot contract freely. This results in tension stresses known as shrinkage stresses. A decrease in temperature relative to that at which the slab was cast, particularly in outdoor structures such as bridge, may have an effect similar to shrinkage. That is, the slab tends to contract and if restrained from doing so becomes subject to tensile stresses.

Since concrete is weak in tension, these temperature and shrinkage stresses are likely to result in cracking. Cracks of this nature are not detrimental, provided their size is limited to what are known as hairline cracks. This can be achieved by placing reinforcement in the slab to counteract contraction and distribution the cracks uniformly. As the concrete tends to shrink, such reinforcement resists the contraction and consequently becomes subject to compression. the total shrinkage in a slab so reinforced is less than that in one without reinforcement in addition, whatever cracks do occur will be of smaller width and more evenly distribution by virtue of the reinforcement.

In one-way slabs, the reinforcement provide for resisting the building moments has the desired effect of reducing shrinkage and distribution cracks. However, as contraction takes place equally in all direction., it is necessary to provided special reinforcement, or distribution steel.

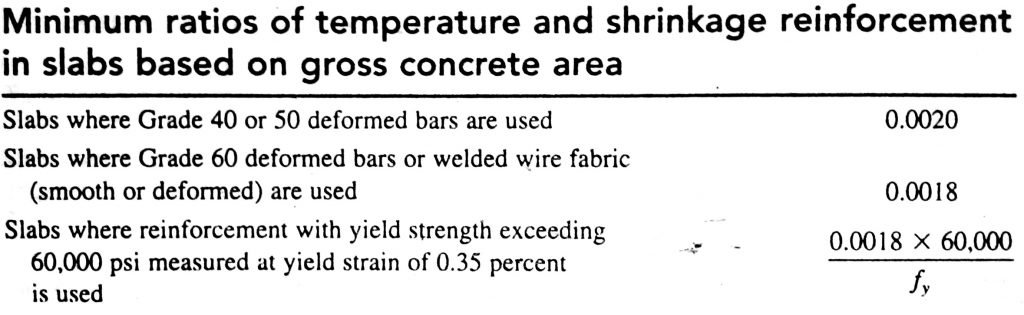

Reinforcement for shrinkage and temperature stresses normal to the principal reinforcement should be provided in a structural slab which the principal reinforcement extends in one direction only. ACI code 7. 12. 2 specifies the minimum ratios of reinforcement area to gross concrete area (i.e. based on the total depth of the slab) shown in Table below, but in no case may such reinforcing bars be placed farther apart than 5 times the slab thickness or more than 18 in. In no case is the reinforcement ratio to be less than 0.0014.

The steel required by the ACI code for shrinkage and temperature crack control also represent the minimum permissible reinforcement in the span direction of one-way slabs; the usual minimum for flexural steel do not apply.

Finally, temperature and shrinkage reinforcement plays an important role for temperature and moisture change. It should be done according to the code.

thank you for your post.

Its very helpful