Cement manufacturing process is not as complex as it seems to be. Industrial manufacturing process of cement definitely involves step by step methodologies. Furthermore, for producing cement, some machines or tools need to be involved. Apart from the tools, a few basic ingredients are also required to make cement. In this piece of writing, the cement making process will be discussed with precision, but before going to that we must have a fair idea about cement. Here are some of the lesser facts and a general synopsis on cement. Understanding this will definitely help to understand the process to make cement:

An Introduction to Cement

Cement is basically a soft, fine and a powder type substance, which is available in the marketplace widely and used for building constructions extensively. It is made up with all natural ingredients, like clay, limestone, sand or shale, etc. When mixed with water and sand, cement can create solid and hard mass, which is generally known as concrete. To make cement, four essential elements are required in a proper ratio and these elements are silicon, calcium, iron and aluminum. Calcium for cement making has been obtained from limestone, which is a natural source of calcium. On the other hand, silicon has been extracted from sand or clay and finally iron as well as aluminum has been derived from iron ore and bauxite respectively. Thus, to make cement, these essential ingredients are required at a proper ratio.

Cement Making Process

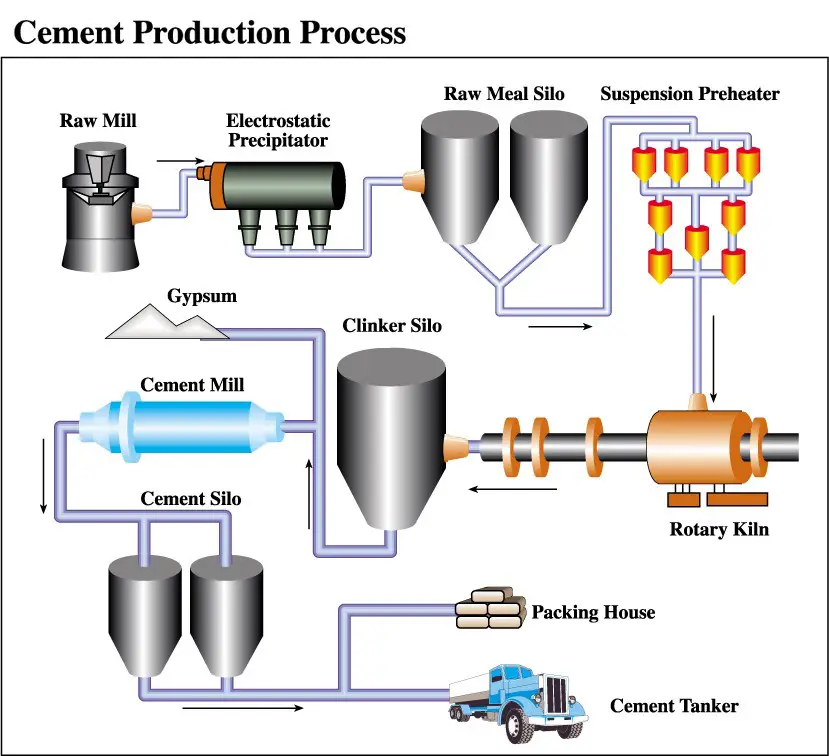

In a broader sense, to make cement, a two step process has to be followed. At the first phase, clinker has been produced with the raw materials and next to that cement has been derived from the produced clinker. According to the state of raw materials or availability of the raw materials, the first phase can be completely dry or completely wet or semi-dry and semi-wet. To make cement, here are the two phases that have to be followed:

-

Making the Clinker

At the initial stage, the nature of the available raw materials has to be checked. Raw materials are generally available in crude forms. An assembly of raw materials has been developed and after that a homogenized mixture of raw materials has been produced. The mixture is produced inside a rotary kiln, which has been universally employed by industrial cement producers to make cement. The kiln is heated up to 2000 degree centigrade flame inside. At this temperature, a perfect mixture of raw materials is usually produced. To make cement, a perfect proportion of four basic oxides are important. Calcium oxide should be 65%, iron oxide should be 5%, alumina oxide should be present at 10% and last but not the least silicon oxide should be present at 20% ratio. At around 2000 degree centigrade temperature inside the kiln, a new substance is produced, known as clinker.

-

From Clinker to Cement

The next phase of cement making is to transform the clinker into cement through grinding mill. Some of the important ingredients are also added in this phase to make cement and they are Gypsum, coal fry ashes, blast furnace slag, etc. Inside the grinding mill, this mixture has been transformed into a homogenous and fine powder. This produced powder is nothing but cement. Manufactured cement is now ready to be stored in silos before being dispatched to the marketplace.

Related: Cement and Concrete – the comparison table

Step by Step Guide for Industrial Cement Making

As mentioned earlier, to make cement, industrial plants follow step by step systematic process. Here is a brief guide on how to make cement:

- At first step, limestone is mixed up with small quantities of sand and clay. It has been ensured that all four basic ingredients (calcium, aluminum, iron and silicon) are present in proper proportion.

- Bolder sized limestone rocks are transported from the quarry to cement plant. The mixture is added into a crusher. The crusher transforms the big sized limestone rocks into smaller rocks.

- The newly produced mixture, then passed through a blender, where smaller sized limestone rocks and other raw materials are ground to the powder form. This is one of the most important steps to make cement.

- Now everything goes into a hot furnace, where at 2000 degree centigrade chemical reactions occur and a new substance is produced, which is generally called as clinker.

- Now, to make cement, clinker has to be cooled down and, then it will be grounded into fine gray powder. This powder is nothing but cement.

Cements are stored in large silos from where they are delivered to marketplaces after being packaged in desired manner, typically inside the sacks.