Septic Tank Construction Methods and Materials

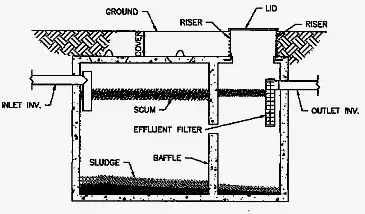

The most important aspect of septic tank construction is that the tank should be installed on a level grade and at a depth that provides adequate gravity flow from the home and matches the invert elevation of the house sewer.

There are some other important notes need to be remembered during septic tank design and construction.

- The tank should be placed on firm ground so that settling is minimum.

- Tank performance can be impaired if a level position is not maintained because the inlet and outlet structures will not function properly.

- Septic tanks must be watertight, structurally durable and stable. As a construction material, reinforced concrete adequately meets these requirements.

- Steel is another material that can be used for septic tanks but should be properly coated for corrosion resistance.

- Plastic and fiberglass tanks can also be used. These are very light, easily transported; provide resistance to corrosion and decay.

- The walls of septic tanks should have a thickness of at least 80 to 100 mm and can also be made of brick work. The important thing is that the tank should be made fully watertight.

- The inlet and outlet pipes should be properly positioned and sealed with concrete or other adhering materials.

You may like to read the following posts:

- How a septic tank system works and

- Advantages and disadvantages of Ventilated Improved Pit Latrine System