Portland cement is the most common type of cement. In particular, “Ordinary Portland cement” is the normal, grey cement with which most people are familiar. Material made by heating a mixture of limestone and clay in a kiln at about 1400 to 1600 degrees (2550 to 2990 F), then grinding to a fine powder with small addition of gypsum.

How to Make Portland Cement

Raw materials for modern cement making:

- Limestones

- argillaceous shales

- Chalks

- schists

- Shells

- clays

- calcareous nodules

- other iron-bearing aluminum-silicates.

Raw Materials Preparation

Cement is typically made from limestone and clay or shale and sand. These raw materials are extracted from the quarry, crushed to a very fine powder and then blended in the correct proportions.

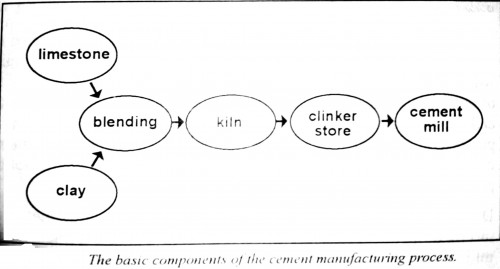

Summary of Manufacturing process

Cement is typically made from limestone and clay or shale. These raw materials are extracted from the quarry to a very fine powder in correct proportions.

This blended raw materials are called the “raw feed” or “kiln feed” and is heated in a rotary kiln where it reaches a temperature of about 1400 c t0 1500 c. In its simplest from, the rotary kiln is a tube up to 200 meters long and perhaps 6 meters in diameter, with a long flame at one end. The raw feed enters the kiln at the cool and end gradually passes down to the hot end,then falls out of the kiln and the cool downs. The material formed in the kiln is described as “clinker” and is typically composed of rounded nodules between 1 mm and 25 mm across. After cooling , the clinker may be stroked temporarily in a clinker store, or it may pass directly to the cement mill. The cement mill grind the clinker to fine powder. A small amount of gypsum – a form of calcium sulfate is normally ground up with the clinker. The gypsum controls the setting properties of the cement when water is added.

Cement manufacturing process in details

Raw materials: The main raw materials used in the cement manufacturing process are limestone, sands, shale, clay and iron ore. The main material is usually mined on site on site while the other minor materials may be mined other on site nearby quarries. Another source of raw materials industrialist by-products.

Raw Material preparation: Mining of limestone requires the use of drilling and blasting techniques. The blasting techniques use the latest technology to insure vibration, dust, and noise emissions are kept at a minimum. Blasting produces materials in a wide range of size from approximately 1.5 meters in diameter. Though a series of the crushes and screens, the limestone is reduced to a size less than 100 mm and stored until required.

Depending on size, the minor materials may or may not be crushed before being stored in separated areas until required.

Raw Grinding

wet process: in the wet process, each raw material is proportioned to meet a desire chemical composition and feed to a rotating ball mill with water. The raw materials are ground to a size where the majority of the materials are less than 75 microns. Materials exciting the mill are called “slurry” and have flow ability character. Following the homogenization process, the slurry is stored in tanks until required.

Dry process: In the dry process, each raw material is proportioned to meet a desired chemical composition and fed to either a rotating ball mill or vertical roller mill. The raw materials are dried with waste process gases and ground to size where the majority of the materials are less then 75 microns. The dry materials exciting either type of mill is called “kiln feed”.

Pyroprocessing

Whether the process is wet or dry, the same chemical reaction take place. Basic chemical reaction are: evaporating all moisture, calcining the limestone to produced free calcium oxide with the minor materials. This results in a fine black, nodular product known as “clinker” which has the diverse hydraulic properties.

Wet process

In the wet process, the slurry is fed to a rotary kiln, which can be from 3.0 m to 5.0 m in diameter and from 120.0 m to 165.0 m in length. The rotary kiln is made of steel and lined with special refractory materials to protect it from the high posses temperature. Posses temperature can reach as high as 1450 C during the clinker making process.

Dry Process

In the dry process, kiln feed is to a preheat tower, which can be as high as 150.0 meters. Materials from the preheated tower is discharged to a rotary kiln with can have the same diameter as a wet posses kiln but the length is much shorter at approximately 45.0 m. The preheated tower and rotary kiln are made of steel and lined with special refractory materials to protect it from the high process temperature.

Regardless of the process, the rotary kiln is fired with an intense flame, produced by burning coal, cock, oil, gas, or waste fuels.

It is very effective creation for civil department. Very helpful site. thanks

i find this useful, thanks…it really helps alot!

Thanks for providing basic knowledge of Preparation of cement. It helped me alot.

Very informative and helpful information. Thank You.