Compacting concrete to where it is solid and can handle a heavy load on it can be tricky and most times it takes concrete vibrators to shift the particles to achieve satisfactory compaction.

Types of Concrete Vibrators

Concrete particles are different sizes and it is best to use vibrators that have different speeds. Vibrators that are used for compacting concrete are many times referred to as poly-frequency vibrators. These are best used for compacting concrete that is of stiff consistency. The frequencies of vibration used are from between 2800 to 15000 rpm. 4 different types of concrete vibrators used for compaction are described in brief below.

1. Needle Vibrators

These are also known as immersion vibrators. It has a steel tube, called a poker, with one end being closed and rounded. There is an eccentric vibrating element inside it. The poker is connected to an electric motor, sometimes a diesel motor, through a flex tube.

These needle vibrators come in a variety of sizes from 40 to 100 mm in diameter. The poker’s diameter is determined by the spacing between the reinforcing bars in the form work. The general range of vibrations for a needle vibrator is between 3000 to 6000 rpm. The period of vibration necessary can be from 30 seconds to 2 minutes and the concrete should be placed in layers no more than 600mm high.

2. Shutter Vibrators

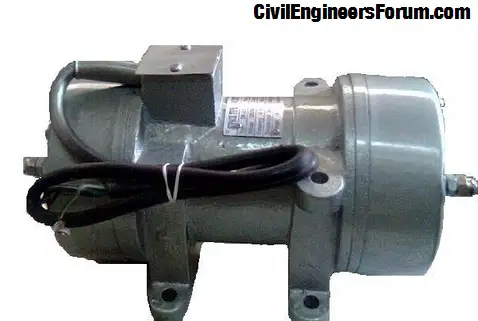

A shutter vibrator is also called an external vibrator and is clamped rigidly to the form work at pre-determined points. This allows for the form and concrete to be vibrated. They are more powerful for a given compaction than an internal vibrator.

These vibrators operate at a frequency of around 3000 to 9000 rpm and an acceleration of 4g. The shutter vibrators are used more often for pre-casting of thin sections that do not have the thickness needed for internal vibrators.

3. Surface Vibrators

Surface vibrators are placed on the concrete mass and are best used for the compaction of shallow elements. These should not be used when the depth of the concrete is more than 250mm.

Mixes that are extremely dry can be most effective compacted using surface vibrators. There are two surface vibrators that are most commonly used: pan vibrators and vibrating screeds. Operating frequency for these vibrators is generally 4000 rpm. The best use for surface vibrators includes small slabs that do not exceed 150mm in thickness.

4. Vibrating Table

A vibrating table is a rigidly built steel platform that is mounted on flexible springs. It is driven by an electric motor. A vibrating table has a normal frequency of 4000 rpm.

These types of vibrators are excellent for compacting harsh concrete mixes that are used for manufactured pre-cast elements such as those in factories or laboratories.