Generally, the temporary structure that is built by timber, plastic or steel to shape casted concrete is called formwork or shuttering. When the casted concrete becomes strengthened, the formwork is taken off.

According to the construction material used, formwork is divided into 3 different types.

- Timber formwork

- Ply wood formwork

- Steel formwork

Necessity of Concrete Formworks

Formwork is needed for the construction of following structural members.

- Wall footing

- Column footing

- Column

- Wall and corner of wall

- RCC beams

- RCC slabs

- RCC stairs

- Shell roof structure

- Dome structure etc.

Essential Requirements of a Good Formwork or Shuttering

A good frame work should have the following characteristics.

- It must be strong so that it can bear the loads of concrete weight, compaction and curing during casting.

- The materials used in formwork or shuttering should be cheap, available and reusable.

- Formworks should be water resistant so that it cannot suck water out of the concrete.

- Formworks should be as light as possible.

- Shuttering should be easy to construct and take off.

- The side which gets in contact with concrete should be smooth.

- The connections will be strong so that it can prevent cement grout leakage.

- The formwork or shuttering should be placed on strong supports.

Advantages of Steel Formworks over Other Formworks

Though steel shuttering is expensive than the other available formworks, it has some advantages that also need to be considered.

- Steel formworks can be easily used again and again.

- The stripping is easier than others.

- It provides smooth and plane surface.

- Steel shutters can bear higher loads.

- It is free from tilting and compaction.

Steps Involved in Formwork Construction

The steps involved in formwork construction involves the followings:

- Propping and centering

- Shuttering construction

- Provision of camber

- Cleaning and surface treatment

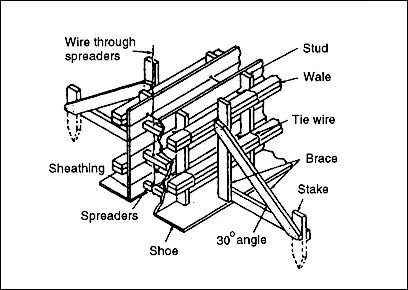

Components of a Formwork or Shuttering

The major components of a concrete formwork are listed below.

- Sheeting

- Yoke

- Wedge

- Cleat

- Batten or joist

- Ledger

- Bolt

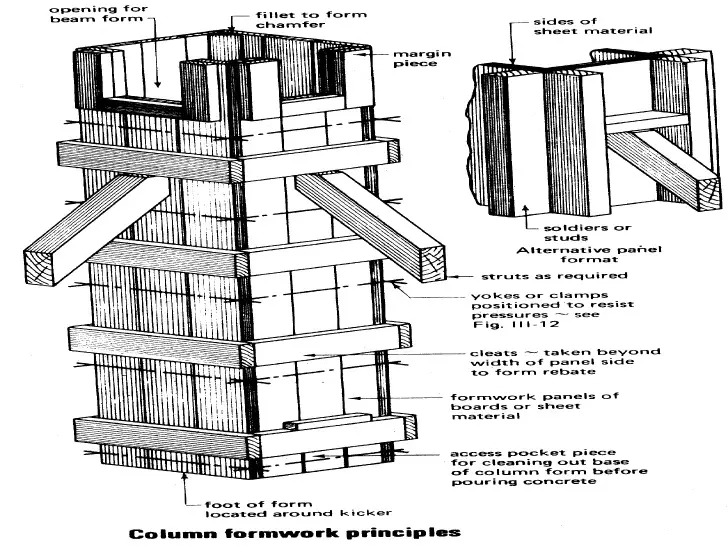

Components of Beam Formwork

Beam formwork includes the following components:

- Cleat

- Side sheeting

- Bottom sheeting

- Ledgers

- Head tree

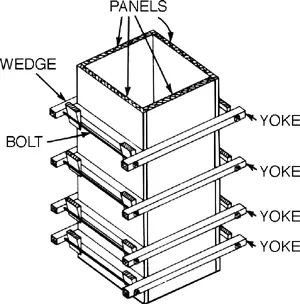

Components of Column Formwork

The column shuttering or formwork includes the components below:

- Sheeting

- Wedges

- Side and end yoke

- Bolt

What are the loads a formwork will need to bear

A formwork or shuttering must to bear the following loads to ensure stability:

- Dead load of casted concrete load.

- Hydrostatic pressure of concrete.

- Live load of the working labors.

- The impact of casting.

- Vibration during compaction.